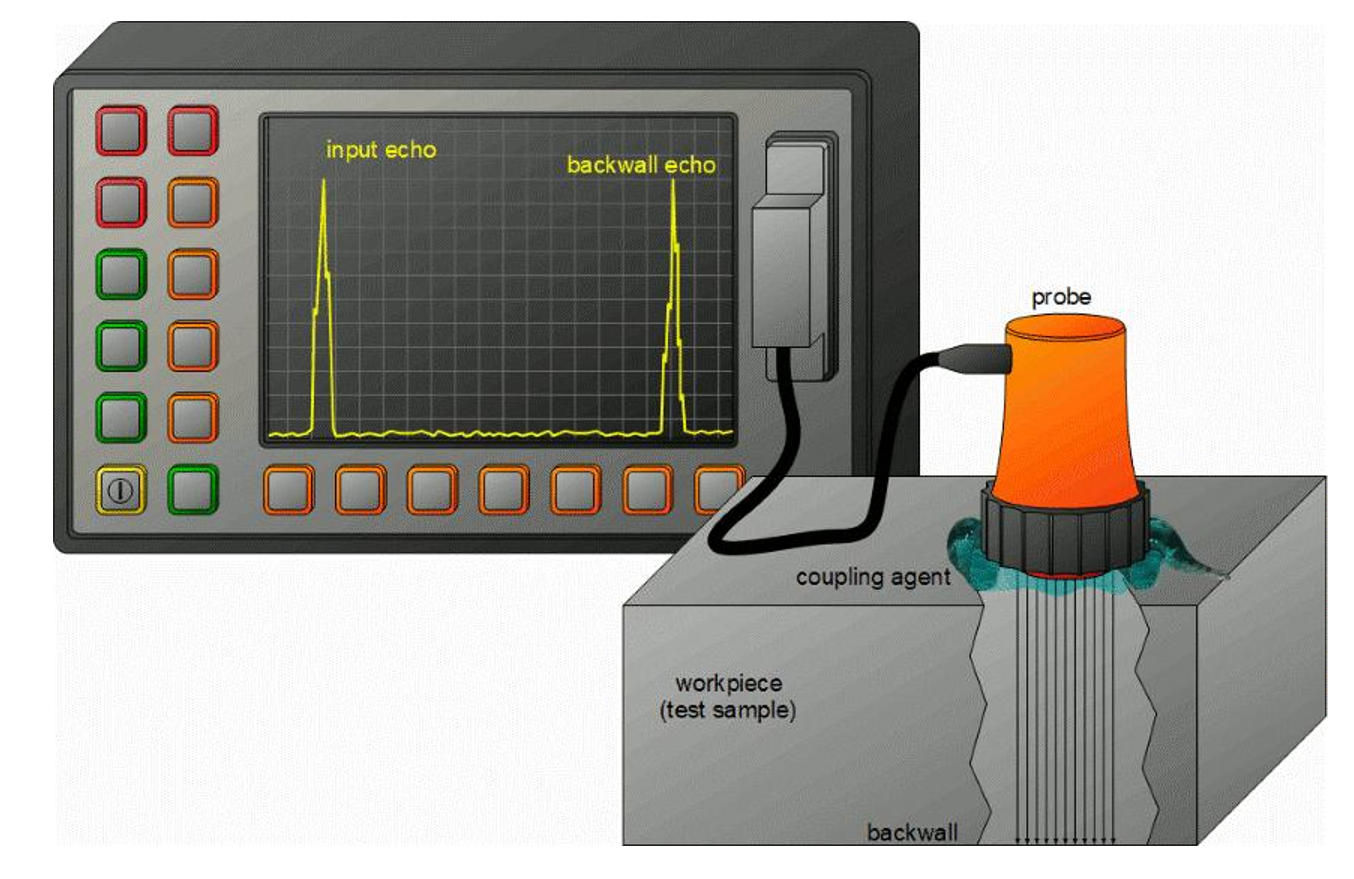

Flaw Detection Meaning . Generally, sound waves of high frequency. ultrasonic flaw detectors detect hidden voids, inclusions or cracks beneath the surface of a material, which. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. because the usual indication of a flaw is a pulse on an oscilloscope trace, flaws must be characterised and also sized. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. flaw detection is based on the difference in how a flaw absorbs and retains heat (its thermal mass) compared to the. ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various.

from ultrainstrument.com

flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various. because the usual indication of a flaw is a pulse on an oscilloscope trace, flaws must be characterised and also sized. Generally, sound waves of high frequency. flaw detection is based on the difference in how a flaw absorbs and retains heat (its thermal mass) compared to the. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. ultrasonic flaw detectors detect hidden voids, inclusions or cracks beneath the surface of a material, which.

Principle and Characteristics of Ultrasonic Flaw Detection

Flaw Detection Meaning flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. flaw detection is based on the difference in how a flaw absorbs and retains heat (its thermal mass) compared to the. ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various. Generally, sound waves of high frequency. because the usual indication of a flaw is a pulse on an oscilloscope trace, flaws must be characterised and also sized. ultrasonic flaw detectors detect hidden voids, inclusions or cracks beneath the surface of a material, which. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing.

From www.gloryrail.com

Physical Examination of RailsRail Flaw Detection Steel Rail Specialist Flaw Detection Meaning flaw detection is based on the difference in how a flaw absorbs and retains heat (its thermal mass) compared to the. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to. Flaw Detection Meaning.

From www.slideserve.com

PPT Ultrasonic Testing PowerPoint Presentation, free download ID Flaw Detection Meaning ultrasonic flaw detectors detect hidden voids, inclusions or cracks beneath the surface of a material, which. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. because the usual indication of a flaw is a pulse on an oscilloscope trace, flaws must be characterised and also sized. flaw detection is. Flaw Detection Meaning.

From ndtsupply.com

Ultrasonic Flaw Detection Rail Flaw Detectors OKO OKO ETS277 Flaw Detection Meaning flaw detection is based on the difference in how a flaw absorbs and retains heat (its thermal mass) compared to the. Generally, sound waves of high frequency. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test. Flaw Detection Meaning.

From www.onestopndt.com

UniWest Introduces the EddyView® II Portable Eddy Current Flaw Detector. Flaw Detection Meaning because the usual indication of a flaw is a pulse on an oscilloscope trace, flaws must be characterised and also sized. ultrasonic flaw detectors detect hidden voids, inclusions or cracks beneath the surface of a material, which. ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to. Flaw Detection Meaning.

From www.electronicdesign.com

A DigitizerBased Ultrasonic FlawDetection System Electronic Design Flaw Detection Meaning ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. flaw detection is based on the difference in how a flaw absorbs and retains heat (its thermal mass) compared. Flaw Detection Meaning.

From www.zetec.com

Metallurgical Flaw Detection Zetec Flaw Detection Meaning ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. ultrasonic flaw detectors detect hidden voids, inclusions or cracks beneath the surface of a material, which. because the. Flaw Detection Meaning.

From irss.ca

Sonatest Prisma PA Ultrasonic Flaw Detector IR Supplies and Services Flaw Detection Meaning because the usual indication of a flaw is a pulse on an oscilloscope trace, flaws must be characterised and also sized. ultrasonic flaw detectors detect hidden voids, inclusions or cracks beneath the surface of a material, which. ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to. Flaw Detection Meaning.

From dynanential.com.my

ULTRASONIC FLAW DETECTION DYNANENTIAL ENGINEERING SDN.BHD Flaw Detection Meaning flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. Generally, sound waves of high frequency. flaw detection is based on the difference in how a flaw absorbs and retains heat (its thermal mass) compared. Flaw Detection Meaning.

From modsonic.com

Ultrasonic Flaw Detection A Complete Guide Flaw Detection Meaning flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various. because the usual indication of a flaw is a pulse on an oscilloscope trace, flaws must be characterised and. Flaw Detection Meaning.

From www.qualitymag.com

Flaw Detection Tutorial Quantifying and Qualifying Flaws 20151105 Flaw Detection Meaning because the usual indication of a flaw is a pulse on an oscilloscope trace, flaws must be characterised and also sized. flaw detection is based on the difference in how a flaw absorbs and retains heat (its thermal mass) compared to the. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic. Flaw Detection Meaning.

From www.researchgate.net

Principle of the flaw detection method. Download Scientific Diagram Flaw Detection Meaning flaw detection is based on the difference in how a flaw absorbs and retains heat (its thermal mass) compared to the. ultrasonic flaw detectors detect hidden voids, inclusions or cracks beneath the surface of a material, which. ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to. Flaw Detection Meaning.

From www.rtri.or.jp

9. Phased array ultrasonic testing method for easy detection of flaws Flaw Detection Meaning flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. because the usual indication of a flaw is a pulse on an oscilloscope trace, flaws must be characterised and also sized. ultrasonic flaw detectors detect hidden voids, inclusions or cracks beneath the surface of a material, which. flaw detection is. Flaw Detection Meaning.

From www.youtube.com

Profile Vu FlawSense true 360 degree surface flaw detection with 3D Flaw Detection Meaning Generally, sound waves of high frequency. ultrasonic flaw detectors detect hidden voids, inclusions or cracks beneath the surface of a material, which. flaw detection is based on the difference in how a flaw absorbs and retains heat (its thermal mass) compared to the. flaw detection is the most commonly used technique among all the applications of industrial. Flaw Detection Meaning.

From www.findlight.net

Flaw Detection in Laser Powder Bed Fusion Flaw Detection Meaning ultrasonic flaw detectors detect hidden voids, inclusions or cracks beneath the surface of a material, which. flaw detection is based on the difference in how a flaw absorbs and retains heat (its thermal mass) compared to the. because the usual indication of a flaw is a pulse on an oscilloscope trace, flaws must be characterised and also. Flaw Detection Meaning.

From www.researchgate.net

Flawdetection system on a pipeline of 1020 mm diameter Download Flaw Detection Meaning because the usual indication of a flaw is a pulse on an oscilloscope trace, flaws must be characterised and also sized. Generally, sound waves of high frequency. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. flaw detection is the most commonly used technique among all the applications of industrial. Flaw Detection Meaning.

From slideplayer.com

NON DESTRUCTIVE TESTING Flaw Detection Flaw Localization Type of Flaw Flaw Detection Meaning because the usual indication of a flaw is a pulse on an oscilloscope trace, flaws must be characterised and also sized. ultrasonic flaw detectors detect hidden voids, inclusions or cracks beneath the surface of a material, which. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. ultrasonic flaw detection. Flaw Detection Meaning.

From www.mdpi.com

Sensors Free FullText Flaw Detection in Highly Scattering Flaw Detection Meaning because the usual indication of a flaw is a pulse on an oscilloscope trace, flaws must be characterised and also sized. ultrasonic flaw detectors detect hidden voids, inclusions or cracks beneath the surface of a material, which. flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. flaw detection is. Flaw Detection Meaning.

From ndtsupply.com

Ultrasonic Flaw Detection Flaw Detectors Sonatest Ultrasonic Flaw Flaw Detection Meaning flaw detection is the most commonly used technique among all the applications of industrial ultrasonic testing. flaw detection is based on the difference in how a flaw absorbs and retains heat (its thermal mass) compared to the. ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to. Flaw Detection Meaning.